Initial Blower Door Air Tightness Test has been carried out this week on our nZEB (nearly-Zero Energy Building) house in Dublin 8. The contract specification set a Q50 target of 1.0 m3/hr.m2 (at 50 Pascals pressurisation), roughly equivalent to the Passive House ‘EnerPHit’ standard for the retrofitting of existing buildings. The refurbished and extended dwelling has achieved an initial air permeability result of 0.8 m3/hr.m2 @50Pa. To put this in context – the maximum permitted air permeability level (for new dwellings) under the current Building Regulations is 7.0 m3/hr.m2 @50Pa, so the nZEB house is achieving an air-tightness standard nearly 10 times that required under the current Regulations.

This ambitious level of structural air-tightness is a vital component of the overall low-energy strategy for the dwelling – reducing to a minimum heat losses occurring through uncontrolled air-infiltration (drafts and air-leaks), whilst also minimising risks of interstitial condensation (moisture vapour passing through the building fabric and condensing on concealed surfaces within the structure). Achieving a high standard of air-tightness was also essential in order to deliver optimum efficiencies from the dwelling’s combined heating and ventilation system – an Exhaust Air Heat Pump, which recovers heat from extracted air and recycles it to provide space heating and domestic hot water.

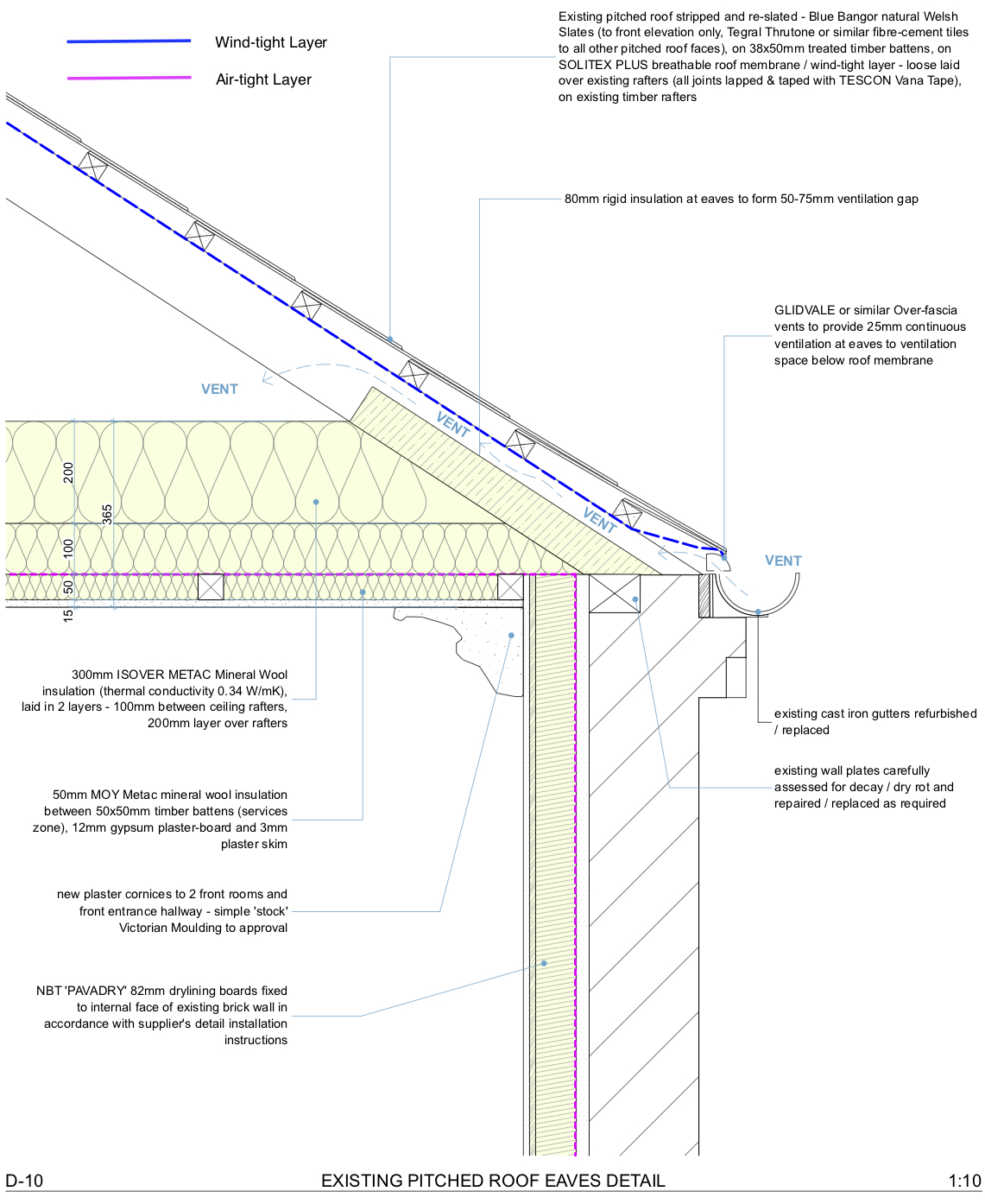

The airtightness level has been achieved by robust detail design, together with careful and diligent execution by the Main Contractor and Sub-Contractors on site. An almost continuous air-tight layer is achieved through the use of wet plaster (walls), double-seals to windows and doors, concrete layers (floor), intelligent air-tight membranes (roof), and with all junctions sealed with air-tight tapes, seals and grommets. A services zone was created to all walls and ceilings to eliminate any chasing or penetrations of the air tight layer.